24/7 ONLINE SUPPORT

Mantles & Bowl Liners That Outperform the Rest

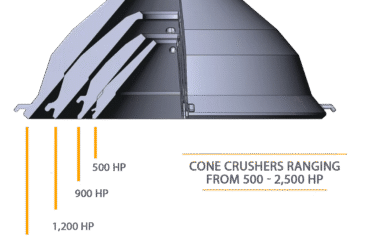

At Optimum Crush, our mantles and bowl liners aren’t just wear parts, they’re engineered solutions. Designed for the most demanding cone crusher applications, our components deliver longer wear life, consistent performance, and reduced downtime. Backed by metallurgy expertise and field-proven results, our liners are trusted by mining and aggregate operations across the globe.

Mantles: Built with Precision, Engineered for Performance

The mantle is the heart of the crushing process. It handles the direct force and abrasion of material flow, making durability and design absolutely critical. At Optimum Crush, we manufacture mantles that are more than just factory replacements. We analyze real wear patterns and operational data to create custom and reengineered profiles that match your specific needs.

Whether you need a one-to-one replacement or a new design to improve performance, our mantles are crafted using high-quality steel alloys and, when needed, integrated hardened inserts for extreme wear environments. Our engineering team works closely with customers to solve challenges like uneven wear, poor throughput, or short liner life.

Bowl Liners: The Foundation of Crusher Longevity

Bowl liners play a vital role in ensuring the efficiency, safety, and longevity of your cone crusher. These liners take on direct compression forces and must maintain proper profile throughout the wear life to keep your crusher performing at its best. At Optimum Crush, we go beyond standard replacement bowl liners, we create solutions that reduce changeouts and enhance overall productivity.

Engineered Liner Review

Our parts are custom-designed to fit your specific mining plan and application, ensuring the perfect match for your operation’s needs. Through detailed wear analysis, we identify opportunities to extend component life and enhance performance. Every design focuses on increasing part longevity and boosting overall production efficiency, keeping your operation running at its best.

Relationships with multiple Foundries

With established relationships across multiple foundries, Optimum Crush minimizes supply chain risks and ensures consistent product availability. This network allows us to secure the best lead times, pricing, and material options for every order, giving you confidence in both quality and reliability.

Our bowl liners are available in a variety of profiles and alloys, and like our mantles, can be customized with hardened inserts for extended performance. Our liners are engineered for even wear, better material flow, and improved mantle-liner engagement. Whether you run a Metso®, FLS®, or Telsmith® machine, our liners are built to last.