VOTE HERE

After viewing the displays online (below) or in person please vote for your favorite here!

All student participants were compensated for this project and additional scholarship funding will be awarded for those involved in the display that receives the most votes during the MinExpo.

Optimum Crush is committed to creating strong partnerships with mines across the globe. Come visit us at the MinExpo 2024 in Las Vegas. Our team will be there to meet with your team and talk through challenges you face with your crushers. Let’s meet so we can work with you to optimize your mine.

We will be in the WEST HALL at Booth #13479

2024 MinExpo Booth

This year’s booth theme is all about our community. Earlier this year we reached a major milestone in our Community Optimization Program, surpassing $1,000,000 in total donations. Each year since 2013, we have helped support the communities around our customer’s mines by donating to local sports teams, creating scholarships, and sponsoring playgrounds and other activity-based facilities.

To help tell that story, we partnered with a local art college, MIAD (Milwaukee Institute of Art & Design), to have students build art interpretations of some of our top-selling parts.

Not only did this project provide invaluable experience to this group of students, it also allowed them to receive scholarship money to help pay for school.

We selected 3 parts for the students to recreate and met with them to explain what Optimum Crush does, what role each part plays in the Cone Crusher machine, and how the crusher machines help mines around the world.

From there, the students created concepts and presented them back to us. We talked through the design ideas and finalized them, and then the students took them from idea to reality. Here is a breakdown of each part they recreated…

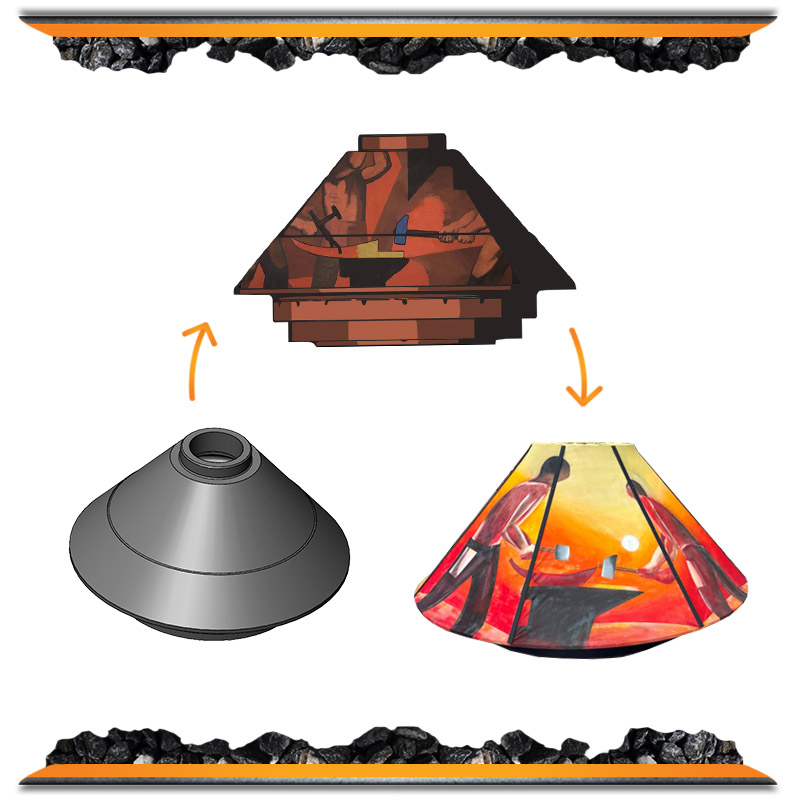

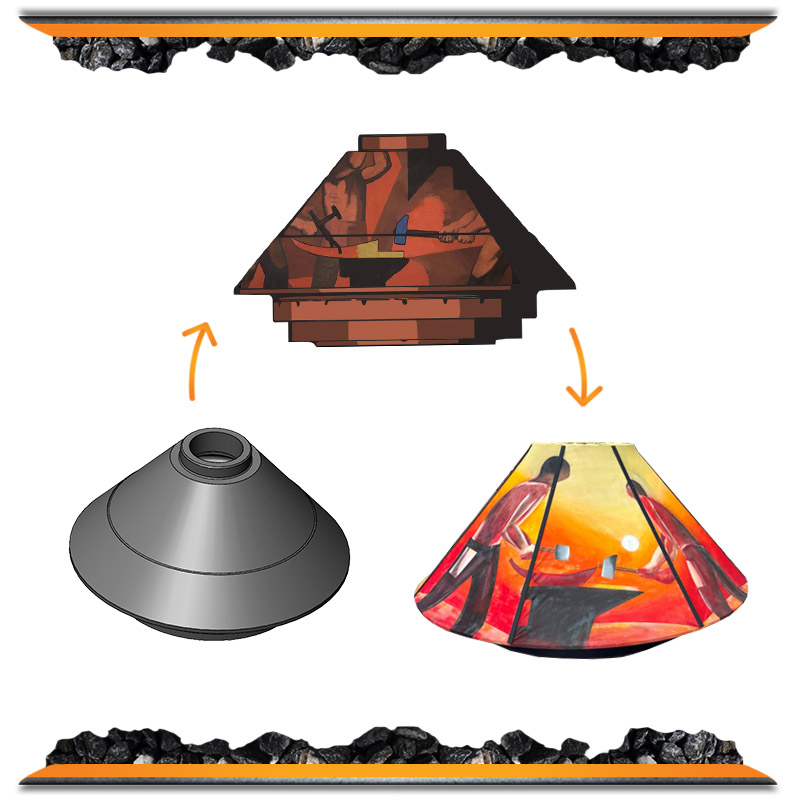

Cone Crusher Head

What we presented to students:

The head is forged in steel and is responsible for the actual crushing action. This part is subject to significant wear due to the constant contact with abrasive material. The key to longevity of this part is the forged material used to create it.

What they came up with:

A “to-scale” head made with wood frame and covered in a painted cloth. Inside the head is a bright light to help make the piece glow to give it a forged look. The painted design on the cloth represents the hard work of the part while also telling the story of being forged. The light has an easy plug for light accessibility. The piece was designed to be light weight and was designed on a stand to be easily moved by a forklift.

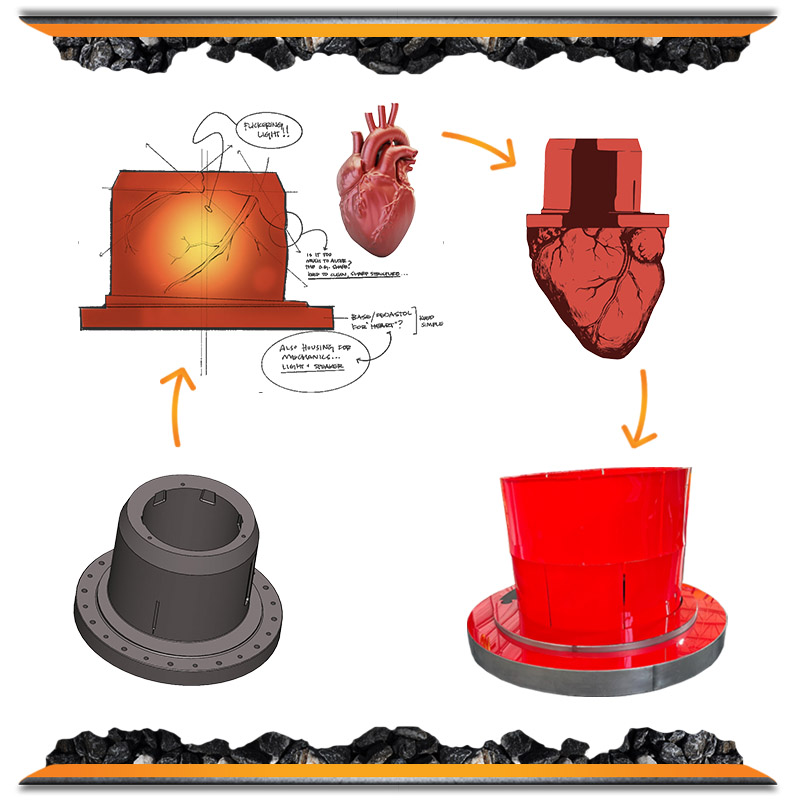

Eccentric

What we presented to students:

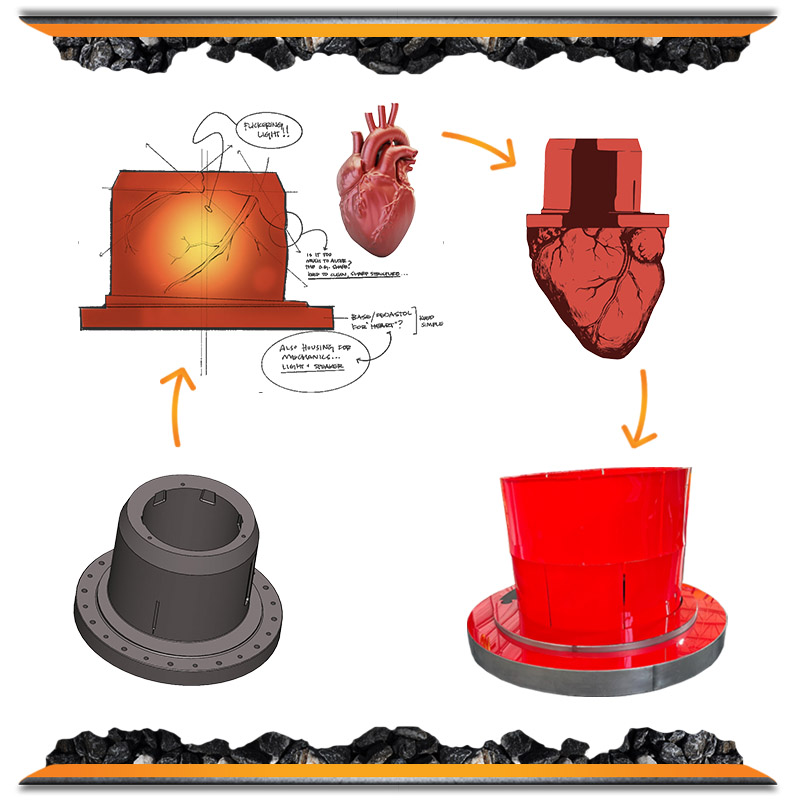

The Eccentric is the “heart” of the machine and drives the unique crushing action of the machine that is necessary for crushing material between the head (Mantle) and Bowl Liner. Similar to the heart of a human body, the Eccentric helps to power the the entire crushing process.

What they came up with:

A “to-scale” Eccentric made with a translucent material to allow for a bright representation of a heart. Inside the display is a 3D printed heart that pulses to truly make the connection of the importance of this part. The light has an easy plug for light accessibility and overall the piece was designed to be light weight. It was designed on a stand to be easily moved by a forklift.

Bowl Liner

What we presented to students:

The Bowl Liner works in tandem with the head to crush rocks in the cone crusher. Each Bowl Liner tells a unique story based on the wear created by crushing rocks. The “story” is the amount of wear and breakdown of material based on the size, frequency, and type of material that runs through it.

What they came up with:

A “to-scale” Bowl Liner that is sliced in half with a large book placed into it. Each side of the Bowl Liner represents something different. On the left (facing) side, the bowl liner is new (Beginning of book). On the right (facing) side the Bowl liner is worn and shows damage and imperfections as it has been in heavy use.

The piece was designed using a wood frame, covered with small precut metal pieces, and then fastened to a stand to be easily moved by a forklift.

It has been fantastic working with Jerrod and his team. Top notch service and products. Quick responses, sage advice, on-site hands on support and great communication make them my first and only call when I have an issue with our cone crushers!

Service & Products

Compared to all of our suppliers, Optimum Crush is the best one out there I’ve worked with. If we have an issue with one of their parts they will resolve it ASAP. They are also always ready to do R&D and help us improve our parts and machines.

Responsive

Optimum Crush is a solid company led by great people. They are always available, knowledgeable and they understand the reality of field work and that we sometimes struggle to use traditional ways to achieve our goals.

Knowledgeable

Free Liner Analysis

Are you ready to optimize your Cone Crusher? Sign up to receive a free liner analysis that can help identify inefficiencies and provide sound data with recommendations to optimize the performance of your crushers.

This means less down time and longer run times. To get started simply fill out the form below and our Account Team will get a call scheduled to learn more.

Why get a FREE Liner Analysis:

- Optimize your current crusher output

- Reduce production down time

- It’s FREE ($15,000 value)

- Our engineers are industry pro’s and know your machines in and out.

- We come to you and will efficiently measure and analyze your machine and provide a full report.

To receive a free liner analysis, you must fill out an application form and meet minimum standards. All analysis testing must be done by our team on site. During COVID-19 related travel restrictions we can only perform these in the US and Canada. As soon as restrictions are lifted, we will resume international requests.

The analysis process involves looking at the current design of your crusher and we focus on the parts with the goal being to increase the liner life. We will examine the castings in new and worn condition and make recommendations on how to increase the life of the parts based on how they wear and sync up. We will use laser scanners to measure parts/equipment, analyze the new and worn liner profiles, identify inefficiencies and then develop and optimize the design to reach project goals.

Our recommendations will be based on the goals to increase liner life, decrease plant shutdowns, increase annual production, decrease operational costs, and reduce annual material costs. This will come with 2D image profiles (sketch) with recommended changes as well as a cost/value analysis and proposal to execute the recommendations.

Want A FREE Analysis?

CRUSH CALCULATOR

Optimum Crush has saved clients millions of dollars each year with our high quality, custom engineered Mantles & Bowl Liners. If you are looking to optimize your mine we should talk.

To see what you can save, please use our Crush Calculator below. Fill in the values in the highlighted cells, based on your companies data, to determine the estimated annual savings due to improvements in liner life. The results are instantly sent to the email you provide.

LET'S CONNECT

We want to hear from you. We have partnered with mines across the globe to provide parts, training and engineering to make their cone crushers run more effectively. To get started, fill out this form and a member of our team will respond within 12 hours.