VOTE HERE

After viewing the displays online (below) or in person please vote for your favorite here!

All student participants were compensated for this project and additional scholarship funding will be awarded for those involved in the display that receives the most votes during the MinExpo.

Optimum Crush is committed to creating strong partnerships with mines across the globe. Come visit us at the MinExpo 2024 in Las Vegas. Our team will be there to meet with your team and talk through challenges you face with your crushers. Let’s meet so we can work with you to optimize your mine.

We will be in the WEST HALL at Booth #13479

2024 MinExpo Booth

This year’s booth theme is all about our community. Earlier this year we reached a major milestone in our Community Optimization Program, surpassing $1,000,000 in total donations. Each year since 2013, we have helped support the communities around our customer’s mines by donating to local sports teams, creating scholarships, and sponsoring playgrounds and other activity-based facilities.

To help tell that story, we partnered with a local art college, MIAD (Milwaukee Institute of Art & Design), to have students build art interpretations of some of our top-selling parts.

Not only did this project provide invaluable experience to this group of students, it also allowed them to receive scholarship money to help pay for school.

We selected 3 parts for the students to recreate and met with them to explain what Optimum Crush does, what role each part plays in the Cone Crusher machine, and how the crusher machines help mines around the world.

From there, the students created concepts and presented them back to us. We talked through the design ideas and finalized them, and then the students took them from idea to reality. Here is a breakdown of each part they recreated…

Cone Crusher Head

What we presented to students:

The head is forged in steel and is responsible for the actual crushing action. This part is subject to significant wear due to the constant contact with abrasive material. The key to longevity of this part is the forged material used to create it.

What they came up with:

A “to-scale” head made with wood frame and covered in a painted cloth. Inside the head is a bright light to help make the piece glow to give it a forged look. The painted design on the cloth represents the hard work of the part while also telling the story of being forged. The light has an easy plug for light accessibility. The piece was designed to be light weight and was designed on a stand to be easily moved by a forklift.

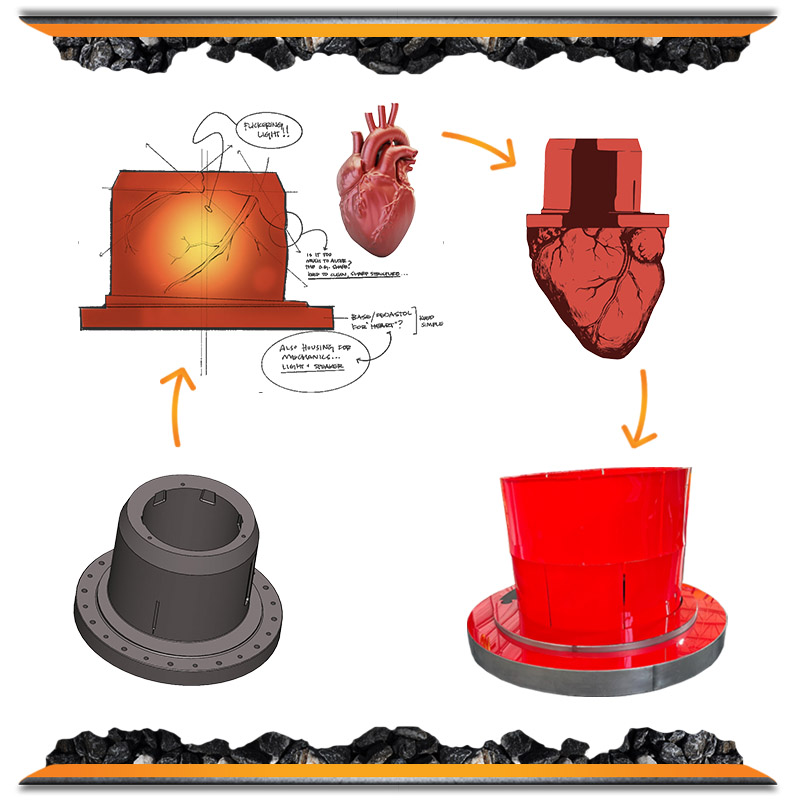

Eccentric

What we presented to students:

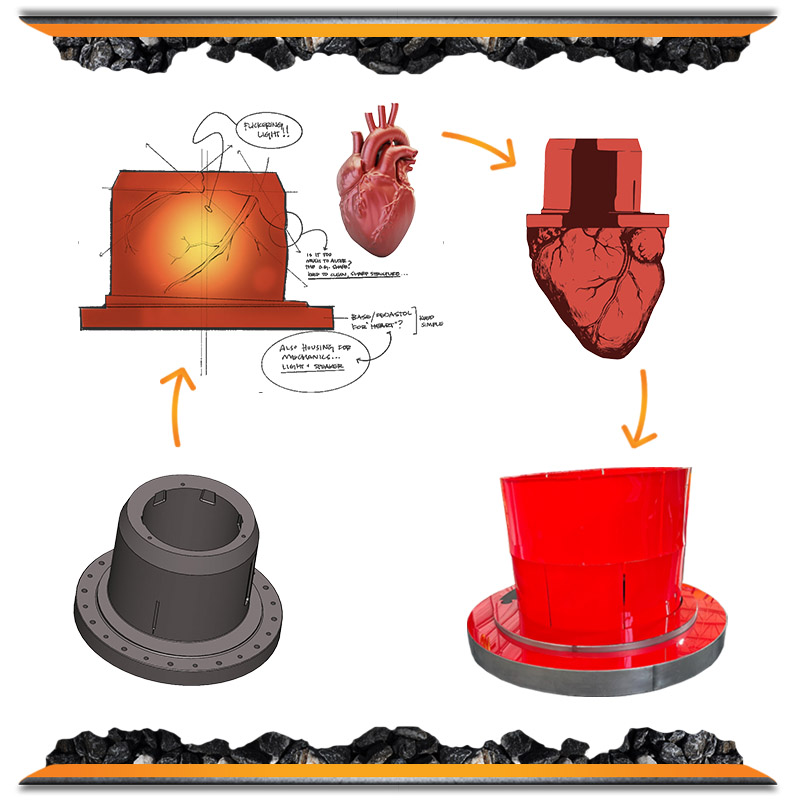

The Eccentric is the “heart” of the machine and drives the unique crushing action of the machine that is necessary for crushing material between the head (Mantle) and Bowl Liner. Similar to the heart of a human body, the Eccentric helps to power the the entire crushing process.

What they came up with:

A “to-scale” Eccentric made with a translucent material to allow for a bright representation of a heart. Inside the display is a 3D printed heart that pulses to truly make the connection of the importance of this part. The light has an easy plug for light accessibility and overall the piece was designed to be light weight. It was designed on a stand to be easily moved by a forklift.

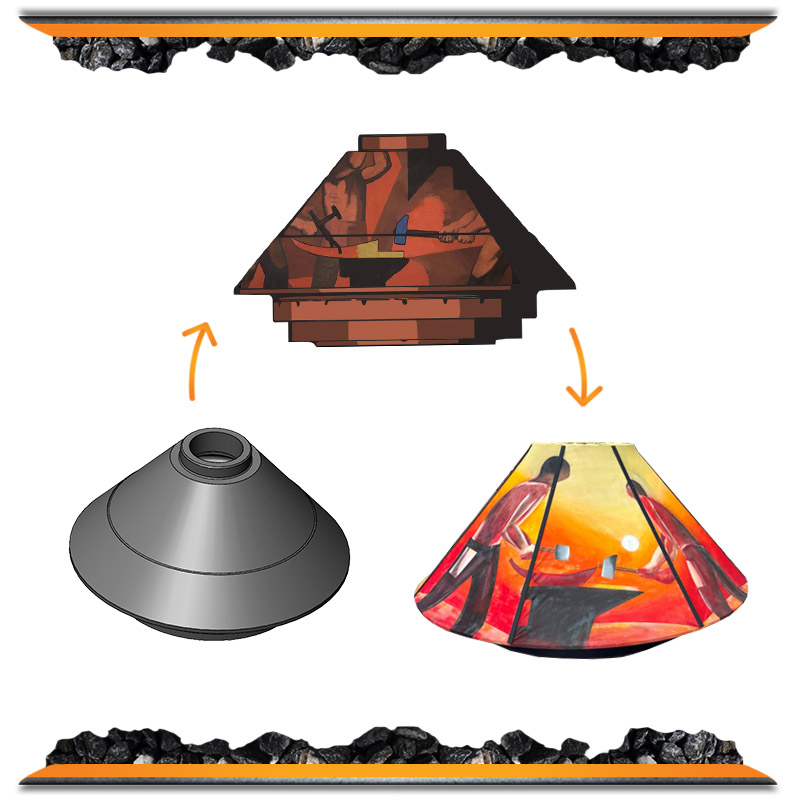

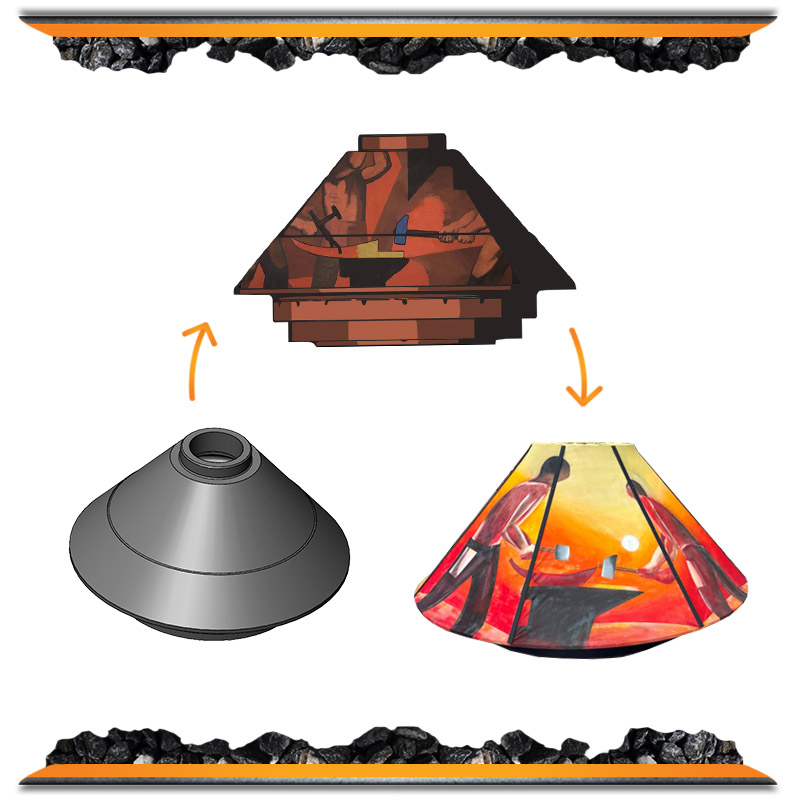

Bowl Liner

What we presented to students:

The Bowl Liner works in tandem with the head to crush rocks in the cone crusher. Each Bowl Liner tells a unique story based on the wear created by crushing rocks. The “story” is the amount of wear and breakdown of material based on the size, frequency, and type of material that runs through it.

What they came up with:

A “to-scale” Bowl Liner that is sliced in half with a large book placed into it. Each side of the Bowl Liner represents something different. On the left (facing) side, the bowl liner is new (Beginning of book). On the right (facing) side the Bowl liner is worn and shows damage and imperfections as it has been in heavy use.

The piece was designed using a wood frame, covered with small precut metal pieces, and then fastened to a stand to be easily moved by a forklift.

Cela a été fantastique de travailler avec Jerrod et son équipe. Service et produits de premier ordre. Des réponses rapides, des conseils avisés, une assistance pratique sur place et une excellente communication en font mon premier et unique appel lorsque j'ai un problème avec nos concasseurs à cône!

Service & Products

Comparé à tous nos fournisseurs, Optimum Crush est le meilleur avec lequel j'ai travaillé. Si nous avons un problème avec l'une de leurs pièces, ils le résoudront dès que possible. Ils sont également toujours prêts à faire de la R&D et à nous aider à améliorer nos pièces et nos machines.

Responsive

Optimum Crush est une entreprise solide dirigée par des gens formidables. Ils sont toujours disponibles, bien informés et ils comprennent la réalité du travail sur le terrain et que nous avons parfois du mal à utiliser les moyens traditionnels pour atteindre nos objectifs.

Knowledgeable

Analyse gratuite des doublures

Are you ready to optimize your Cone Crusher? Sign up to receive a free liner analysis that can help identify inefficiencies and provide sound data with recommendations to optimize the performance of your crushers.

Cela signifie moins de temps d'arrêt et des temps de fonctionnement plus longs. Pour commencer, remplissez simplement le formulaire ci-dessous et notre équipe de compte recevra un appel prévu pour en savoir plus.

Pourquoi obtenir une analyse de doublure GRATUITE:

- Optimisez la production actuelle de votre concasseur

- Réduisez les temps d'arrêt de production

- C'est GRATUIT (valeur de 15 000 $)

- Nos ingénieurs sont des professionnels du secteur et connaissent parfaitement vos machines.

- Nous venons à vous et mesurerons et analyserons efficacement votre machine et vous fournirons un rapport complet.

Pour recevoir une analyse de doublure gratuite, vous devez remplir un formulaire de demande et répondre aux normes minimales. Tous les tests d'analyse doivent être effectués par notre équipe sur place. Pendant les restrictions de voyage liées au COVID-19, nous ne pouvons les effectuer qu'aux États-Unis et au Canada. Dès que les restrictions seront levées, nous reprendrons les demandes internationales.

Le processus d'analyse consiste à examiner la conception actuelle de votre concasseur et nous nous concentrons sur les pièces dans le but d'augmenter la durée de vie du revêtement. Nous examinerons les pièces moulées à l'état neuf et usé et ferons des recommandations sur la façon d'augmenter la durée de vie des pièces en fonction de leur usure et de leur synchronisation. Nous utiliserons des scanners laser pour mesurer les pièces / équipements, analyser les profils de doublure neufs et usés, identifier les inefficacités, puis développer et optimiser la conception pour atteindre les objectifs du projet.

Nos recommandations seront basées sur les objectifs d'augmentation de la durée de vie des chemises, de réduction des arrêts d'usine, d'augmentation de la production annuelle, de réduction des coûts opérationnels et de réduction des coûts annuels des matériaux. Cela viendra avec des profils d'image 2D (croquis) avec les changements recommandés ainsi qu'une analyse coût / valeur et une proposition pour exécuter les recommandations.

Vous voulez une analyse GRATUITE?

CALCULATEUR D'ÉCRASEMENT

Optimum Crush a permis à ses clients d'économiser des millions de dollars chaque année grâce à nos pièces de concasseur de haute qualité conçues sur mesure. Si vous cherchez à optimiser votre mine, nous devrions en parler.

Pour voir ce que vous pouvez économiser, veuillez utiliser notre calculateur de broyeur ci-dessous. Modifiez les valeurs dans les cellules en surbrillance pour déterminer les économies annuelles estimées grâce à l'amélioration de la durée de vie des chemises.

LET'S CONNECT

We want to hear from you. We have partnered with mines across the globe to provide parts, training and engineering to make their cone crushers run more effectively. To get started, fill out this form and a member of our team will respond within 12 hours.