VOTE HERE

After viewing the displays online (below) or in person please vote for your favorite here!

All student participants were compensated for this project and additional scholarship funding will be awarded for those involved in the display that receives the most votes during the MinExpo.

Optimum Crush is committed to creating strong partnerships with mines across the globe. Come visit us at the MinExpo 2024 in Las Vegas. Our team will be there to meet with your team and talk through challenges you face with your crushers. Let’s meet so we can work with you to optimize your mine.

We will be in the WEST HALL at Booth #13479

2024 MinExpo Booth

This year’s booth theme is all about our community. Earlier this year we reached a major milestone in our Community Optimization Program, surpassing $1,000,000 in total donations. Each year since 2013, we have helped support the communities around our customer’s mines by donating to local sports teams, creating scholarships, and sponsoring playgrounds and other activity-based facilities.

To help tell that story, we partnered with a local art college, MIAD (Milwaukee Institute of Art & Design), to have students build art interpretations of some of our top-selling parts.

Not only did this project provide invaluable experience to this group of students, it also allowed them to receive scholarship money to help pay for school.

We selected 3 parts for the students to recreate and met with them to explain what Optimum Crush does, what role each part plays in the Cone Crusher machine, and how the crusher machines help mines around the world.

From there, the students created concepts and presented them back to us. We talked through the design ideas and finalized them, and then the students took them from idea to reality. Here is a breakdown of each part they recreated…

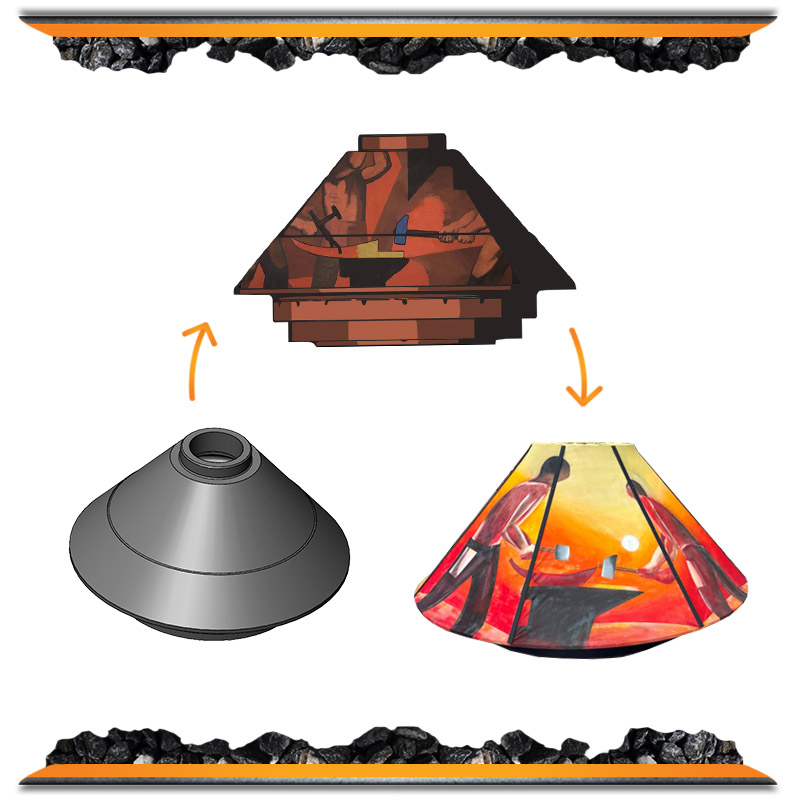

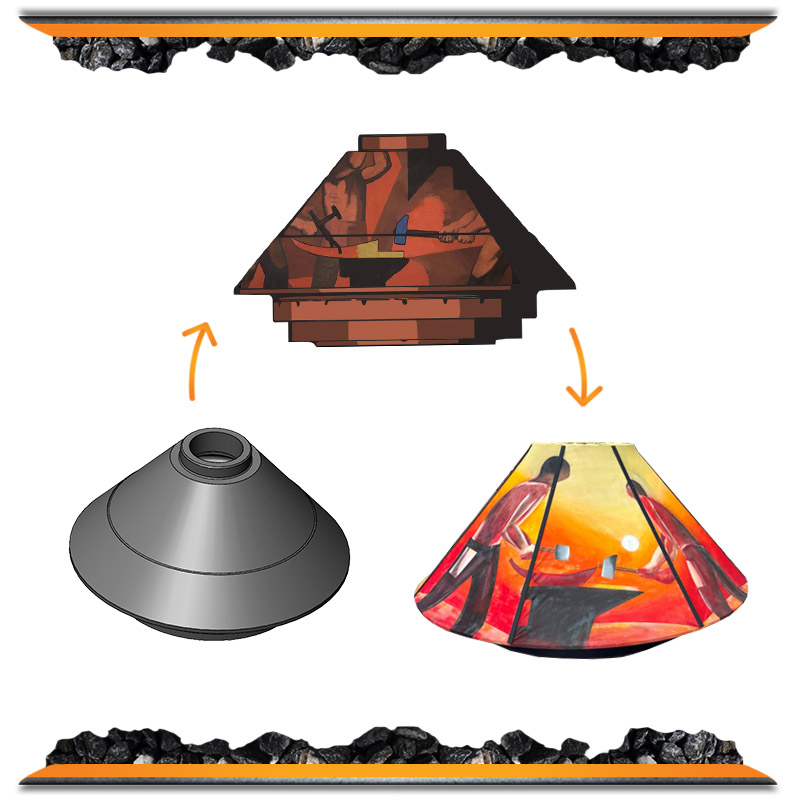

Cone Crusher Head

What we presented to students:

The head is forged in steel and is responsible for the actual crushing action. This part is subject to significant wear due to the constant contact with abrasive material. The key to longevity of this part is the forged material used to create it.

What they came up with:

A “to-scale” head made with wood frame and covered in a painted cloth. Inside the head is a bright light to help make the piece glow to give it a forged look. The painted design on the cloth represents the hard work of the part while also telling the story of being forged. The light has an easy plug for light accessibility. The piece was designed to be light weight and was designed on a stand to be easily moved by a forklift.

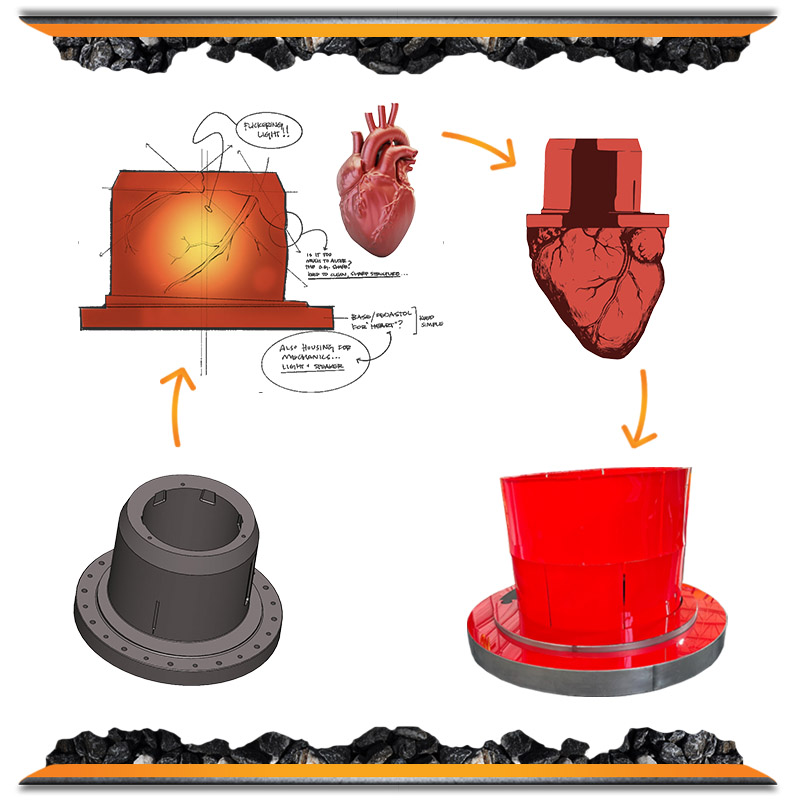

Excéntrico

What we presented to students:

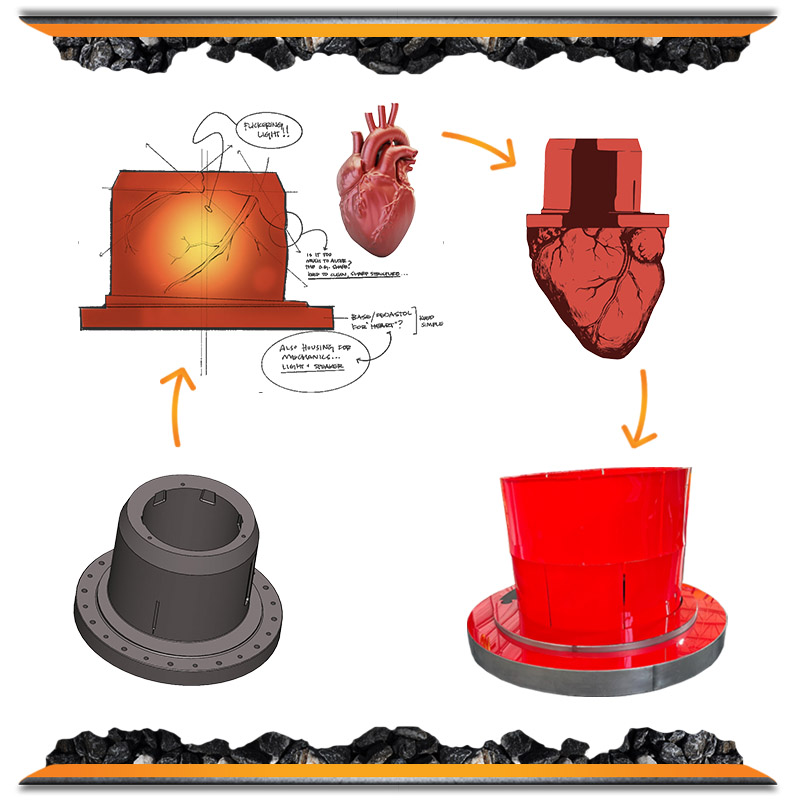

The Eccentric is the “heart” of the machine and drives the unique crushing action of the machine that is necessary for crushing material between the head (Mantle) and Bowl Liner. Similar to the heart of a human body, the Eccentric helps to power the the entire crushing process.

What they came up with:

A “to-scale” Eccentric made with a translucent material to allow for a bright representation of a heart. Inside the display is a 3D printed heart that pulses to truly make the connection of the importance of this part. The light has an easy plug for light accessibility and overall the piece was designed to be light weight. It was designed on a stand to be easily moved by a forklift.

Bowl Liner

What we presented to students:

The Bowl Liner works in tandem with the head to crush rocks in the cone crusher. Each Bowl Liner tells a unique story based on the wear created by crushing rocks. The “story” is the amount of wear and breakdown of material based on the size, frequency, and type of material that runs through it.

What they came up with:

A “to-scale” Bowl Liner that is sliced in half with a large book placed into it. Each side of the Bowl Liner represents something different. On the left (facing) side, the bowl liner is new (Beginning of book). On the right (facing) side the Bowl liner is worn and shows damage and imperfections as it has been in heavy use.

The piece was designed using a wood frame, covered with small precut metal pieces, and then fastened to a stand to be easily moved by a forklift.

Ha sido fantástico trabajar con Jerrod y su equipo. Servicio y productos de primera categoría. Las respuestas rápidas, los sabios consejos, el apoyo práctico en el lugar y la excelente comunicación los convierten en mi primera y única llamada cuando tengo un problema con nuestras trituradoras de cono.

Service & Products

En comparación con todos nuestros proveedores, Optimum Crush es el mejor con el que he trabajado. Si tenemos un problema con una de sus partes, lo resolverán lo antes posible. También están siempre dispuestos a realizar I + D y ayudarnos a mejorar nuestras piezas y máquinas.

Responsive

Optimum Crush es una empresa sólida dirigida por grandes personas. Siempre están disponibles, tienen conocimientos y comprenden la realidad del trabajo de campo y que a veces nos cuesta usar las formas tradicionales para lograr nuestros objetivos.

Knowledgeable

Análisis de revestimiento libre

Are you ready to optimize your Cone Crusher? Sign up to receive a free liner analysis that can help identify inefficiencies and provide sound data with recommendations to optimize the performance of your crushers.

Esto significa menos tiempo de inactividad y tiempos de ejecución más largos. Para comenzar, simplemente complete el formulario a continuación y nuestro equipo de cuentas recibirá una llamada programada para obtener más información.

Por qué obtener un análisis de revestimiento GRATIS:

- Optimice la producción actual de su trituradora

- Reducir el tiempo de inactividad de la producción

- Es GRATIS (valor de $ 15,000)

- Nuestros ingenieros son profesionales de la industria y conocen bien sus máquinas.

- Acudimos a usted y mediremos y analizaremos su máquina de manera eficiente y le proporcionaremos un informe completo.

Para recibir un análisis de revestimiento gratuito, debe completar un formulario de solicitud y cumplir con los estándares mínimos. Todas las pruebas de análisis deben ser realizadas por nuestro equipo en el sitio. Durante las restricciones de viaje relacionadas con COVID-19, solo podemos realizarlas en los EE. UU. Y Canadá. Tan pronto como se levanten las restricciones, reanudaremos las solicitudes internacionales.

El proceso de análisis implica observar el diseño actual de su trituradora y nos enfocamos en las partes con el objetivo de aumentar la vida útil del revestimiento. Examinaremos las piezas fundidas en condiciones nuevas y desgastadas y haremos recomendaciones sobre cómo aumentar la vida útil de las piezas en función de cómo se desgastan y sincronizan. Usaremos escáneres láser para medir piezas / equipos, analizar los perfiles de revestimiento nuevos y desgastados, identificar ineficiencias y luego desarrollar y optimizar el diseño para alcanzar los objetivos del proyecto.

Nuestras recomendaciones se basarán en los objetivos de aumentar la vida útil del revestimiento, disminuir las paradas de la planta, aumentar la producción anual, disminuir los costos operativos y reducir los costos anuales de materiales. Esto vendrá con perfiles de imagen 2D (croquis) con los cambios recomendados, así como un análisis de costo / valor y una propuesta para ejecutar las recomendaciones.

¿Quiere un análisis GRATIS?

CALCULADORA DE CRUSH

Optimum Crush ha ahorrado a los clientes millones de dólares cada año con nuestras piezas trituradoras de alta calidad diseñadas a medida. Si está buscando optimizar su mina, deberíamos hablar.

Para ver lo que puede ahorrar, utilice nuestra calculadora trituradora a continuación. Edite los valores en las celdas resaltadas para determinar los ahorros anuales estimados debido a las mejoras en la vida útil del revestimiento.

LET'S CONNECT

We want to hear from you. We have partnered with mines across the globe to provide parts, training and engineering to make their cone crushers run more effectively. To get started, fill out this form and a member of our team will respond within 12 hours.